What factors affect the quality of carbide milling cutter?

Analysis of the key factors of carbide milling cutter quality

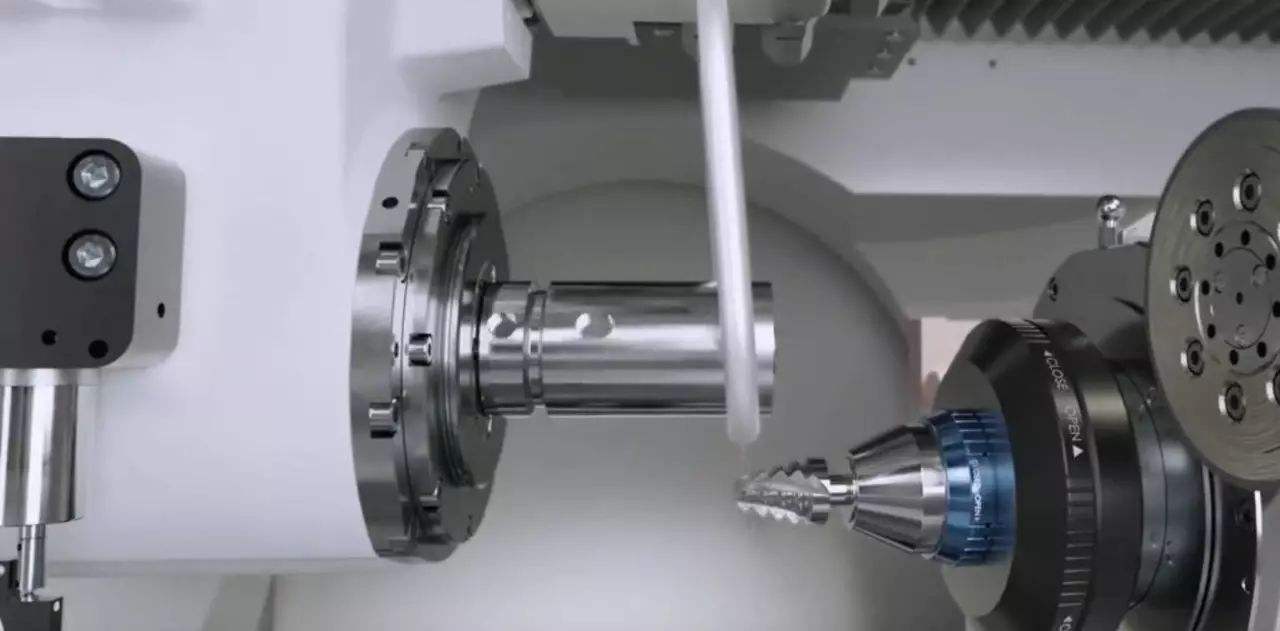

(I) hardness and resistance

Cemented carbide milling cutter has unique advantages in hardness and durability. Tungsten carbide (WC) itself has a high hardness (beyond corundum or alumina), and its hardness rarely decreases with the increase of working temperature. However, it lacks enough endurance, which is essential for cutting tools. In order to use the high hardness of tungsten carbide and improve its resistance, metal bond is used to combine tungsten carbide together, so that the material can not only have a hardness far higher than that of high speed steel, but also can accept the cutting force in most cutting processes. In addition, it can also accept the high cutting temperature generated by high-speed machining.

Therefore, the adaptability of cemented carbide milling cutter performance to specific machining depends largely on the initial milling process.

(2) milling process of cemented carbide milling cutter

Tungsten carbide powder is obtained by carburizing tungsten (W) powder. The characteristics of tungsten carbide powder (especially its particle size) mainly depend on the particle size of tungsten powder and carburizing temperature and time. Chemical control is also essential, and it is necessary to keep the carbon content constant. A small amount of vanadium and / or chromium can be added before carburizing in order to control the particle size of the powder through subsequent processes. The combination of tungsten carbide particle size, carbon content, vanadium content and chromium content is selected according to the different process conditions and processing requirements of cemented carbide milling cutter. After these combinations change, various tungsten carbide powders can be produced.

Source: Zhongshan tungsten steel milling cutter http://www.gdsgdj.com

-

10-12

What are the causes of chip accretion on NC tools?

The reason is that the chip bottom metal is embedded in the micro uneven peak valley on the front cutter surface due to the large down pressure in the part close to the cutting edge, forming a gap free metal to metal touch, which is called the bonding area. In the bonding zone, there will be a thin layer of metal data accumulated on the rake face at the bottom of the chip. The metal data of this part of the chip is severely deformed and strengthened at the appropriate cutting temperature. With t

-

10-12

What are the wear types of tungsten steel milling cutters?

Abrasive wear machining materials often have some very hard particles, these particles will form grooves on the surface of the tool, which is the grinding loss. All surfaces are worn, especially the rake face. In addition, although the wear of hemp occurs at various cutting speeds, the wear caused by other reasons is not obvious due to the low cutting temperature at low cutting speed, so it is mainly the abrasion of abrasive materials. The lower the tool hardness is, the more serious the grindin